Towards Effective Defence Procurement: Lessons from the US SPEED Act 2025

- November 07, 2025 |

- Issue Brief

Summary

India’s defence procurement continues to suffer from protracted timelines, bureaucratic bottlenecks and escalating costs. This brief highlights some key aspects of the US Streamlining Procurement for Effective Execution and Delivery (SPEED) Act 2025, which prioritises agility, concurrent processing, empowered leadership, and outcome-based frameworks to reduce acquisition cycles.

Introduction

Defence procurement shapes a nation’s military preparedness and strategic autonomy. In India, defence procurement continues to be dogged by complexity and delay. The Defence Acquisition Procedure (DAP) 2020 was intended to harmonise transparency, accountability and indigenisation under the vision of Atmanirbhar Bharat. However, its sequential and compliance-heavy design often becomes a deterrent rather than an enabler.[i] Long procurement cycles erode deterrence, inflate costs and leave frontline units to operate legacy systems at a time when adversaries are modernising rapidly. Beyond equipment, such inefficiencies affect confidence in India’s ability to align its economic, technological and strategic ambitions with its security needs.

Globally, there is a visible trend towards agile procurement frameworks that prioritise speed, adaptability and outcome-oriented processes. The United States, for example, has introduced the Streamlining Procurement for Effective Execution and Delivery (SPEED) Bill 2025 (known as the SPEED Act, H.R. 3838), introduced in the House of Representatives on 9 June 2025 which shifts focus from voluminous paperwork to rapid prototyping, empowered leadership and digital decision-making. Rather than prescribing rigid specifications, it frames problems around capability gaps and fosters innovation through industry–government collaboration.[ii]

For India, studying such models is not about wholesale adoption but about deriving actionable lessons that align with its unique political, industrial and security ecosystem. The brief situates India’s procurement dilemmas within this comparative context, asking whether selective adaptation of SPEED-inspired mechanisms—such as Joint Requirements Councils, Programme Executive Officer models, and modular contracting—could pave the way for a procurement culture that is faster, more accountable and strategically future-proof.[iii]

Indian Acquisition System: Current Process

The Defence Acquisition Procedure (DAP) 2020 governs India’s procurement framework, designed to ensure transparency, accountability and support for Atmanirbhar Bharat. The procedure begins with identifying Defence Capability Gaps through the Long Term Integrated Perspective Plan (LTIPP) and the Services Capital Acquisition Plan (SCAP). These are prioritised under the Annual Acquisition Plan (AAP). Next follows the Acceptance of Necessity (AoN) stage, wherein proposals are scrutinised for operational need, affordability and indigenous content. Post-AoN, Solicitation of Offers is initiated through Request for Information (RFI) and Request for Proposal (RFP).

Subsequently, Bid Evaluation ensues under the ‘two-bid system’—technical and commercial—to ensure fairness and transparency. After technical compliance, the Field Evaluation Trials (FETs) and Staff Evaluation validate operational parameters in real conditions. Following this, Technical Oversight Committees and Contract Negotiation Committees (CNCs) conduct detailed cost, commercial and legal negotiations. Once the Competent Financial Authority (CFA) approves, the process culminates in Contract Signing. Thereafter, Pre-production Clearance and Quality Assurance phases ensure adherence to specifications.

The Delivery and Acceptance stage formalises induction into service, followed by Post-Contract Management, which covers warranty, life-cycle support and performance monitoring. Finally, the Offsets and Make-in-India provisions ensure the creation of domestic capability. Collectively, these stages reflect DAP-2020’s emphasis on Atmanirbharta (self-reliance), accountability and efficiency in India’s defence acquisition ecosystem.[iv] Despite these layered safeguards, the process remains sequential, paperwork-intensive and risk-averse, often stretching acquisition timelines to 7–10 years and adversely impacting operational readiness.

SPEED Act 2025

The traditional US Defence Acquisition System (DAS) followed sequential, milestone-driven phases—Materiel Solution Analysis, Technology Maturation, Engineering & Manufacturing Development, Production & Deployment, and Operations & Support—characterised by heavy documentation and multiple approvals.[v] While ensuring accountability, it led to rigid specifications, vendor lock-ins and long timelines of 7–10 years. The SPEED Act 2025 counters this through an agile, outcome-based framework where capability development begins with user needs and joint operational framing. Technology maturation merges with agile prototyping for rapid iteration and fail-fast testing, while engineering adopts modular build-test-refine loops for incremental fielding. Supported by empowered Programme Executive Officers (PEOs), adaptive funding and digital dashboards, SPEED embeds concurrency and user-driven innovation—cutting timelines to 90–150 days and removing the bureaucratic rigidity of the traditional system.[vi]

Table 1. Comparison of Traditional US DAS and SPEED Act 2025

| Category | Traditional US DAS | SPEED Act 2025 |

| Process Flow | Sequential, milestone-driven phases (Materiel Solution → Tech Maturation → Engg & Manufacturing → Production → Support) | Agile, outcome-based, concurrent processes (User Needs → Joint Ops Problem Framing) |

| Documentation & Requirements | Heavy documentation, multiple approvals, and rigid specifications | Operationally driven, adaptive requirements |

| Development Approach | Waterfall-style development cycles | Agile Tech + Engineering: iterative build–test–refine cycles |

| Technology Management | Technology gatekeeping, slow risk reduction | Rapid prototyping, Pathfinder Programmes, fail-fast testing |

| Industrial Strategy | Large single-vendor contracts, limited industrial flexibility | Modular contracts, multi-vendor pools, flexible scaling |

| Timeline | Long timelines (7–10 years) before capability delivery | Short timelines (90–150 days) for decision-to-fielding |

| Feedback & Adaptability | Feedback loop late in the lifecycle, minimal operator influence | Continuous deployment with operator-driven feedback loops |

Mapping DAP 2020 and SPEED Act 2025: A Comparative Analysis

Process Orientation

DAP 2020 operates through a linear, sequential chain (RFI → SQR → AoN → RFP → Trials → CNC/Contract). This rigid phasing often stretches acquisition timelines into several years. The SPEED Act establishes an iterative, outcome-oriented process with concurrent decision-making and dynamic governance mechanisms. This ensures that capability requirements evolve alongside operational realities, enabling quicker, more relevant delivery.

Requirements Framing

In DAP, Service Qualitative Requirements (SQRs) form the backbone of acquisition, categorised as essential and desirable. While precise, they often lock capability into specifications that may soon be outdated. The SPEED Act reframes requirements into Outcome Briefs, prepared under Joint Requirements Councils (JRCs) and the RAPID framework. This encourages experimentation and iterative feedback at early stages, preventing stagnation.

Contracting Pathways

Traditional contracting in DAP emphasises leasing, Buy/Make categories, and offsets, with limited space for agility. By contrast, SPEED creates flexible pathways such as Other Transaction Authorities (OTAs). OTAs are special, legally binding agreements exempt from standard Federal Acquisition Regulation rules. They expand participation to non-traditional vendors, research organisations, and start-ups; accelerate prototyping and fielding timelines; and reduce procedural complexity. OTAs are especially effective for projects involving innovative technologies or short development cycles, and have been widely used in the United States for ventures such as research, R&D and follow-on production. These authorities could be adapted to India for projects where flexibility and private-sector participation are critical. OTAs typically require significant input from non-traditional defence contractors or cost-sharing arrangements, focusing on collaborative, high-impact deliverables.

Technology and Industrial Strategy

DAP encourages Transfer of Technology (ToT) and indigenous content, but these remain framed within a relatively narrow offset-based industrial strategy. SPEED leverages Modular Open Systems Architecture (MOSA), an integrated business and technical approach to enable competitive, affordable and flexible acquisition and sustainment of defence systems throughout their lifecycle. MOSA is both a design philosophy and an acquisition mandate, required by US defence law for all major defence programmes, like F-35, Navy ships and Army ground vehicles, all of which use MOSA principles to accelerate upgrades and innovate operational capabilities and is increasingly adopted worldwide as a best practice in complex military systems.

DAP 2020 already signals a move towards modular, upgradable and interoperable systems, especially under ‘Make’ and ‘Buy & Make’ categories. For India to leverage MOSA fully:

- Enable competitive modular procurement: Structure contracts and evaluation so major platforms (aircraft, vehicles, electronics) are procured as a base system with interchangeable modules (radars, software, weapons, communications) that can be competed and sourced over time.

- Facilitate upgrades and vendors: Allow rapid integration of Indian-developed tech or start-up solutions through plug-and-play compliance, rather than requiring modification of entire platforms.

- Promote lifecycle cost reduction: MOSA makes upgrades, repairs and enhancements more cost-effective and less dependent on a single vendor, reducing ownership costs and supporting Make in India goals.

- Foster interoperability: Using open standards, Indian solutions can be compatible with allied nations and partner systems, advancing joint operations and global export markets.

Governance and Oversight

Governance in DAP is document-centric, paper-driven and heavily layered, resulting in significant decision bottlenecks. SPEED replaces this with streamlined digital reporting, modernised training and Programme Executive Officers (PEOs) empowered with budget re-phasing and decision authority. This digital-first approach preserves accountability while dramatically accelerating decision cycles.

Testing and Trials

Under DAP, user trials are lengthy, protocol-heavy and duplicative, causing delays and scope creep. The SPEED Act introduces Agile OT&E (Operational Test & Evaluation). Agile OT&E involves iterative, fail-fast test cycles, where prototypes are regularly assessed and programmes can be terminated early if they fail to meet operational benchmarks. Unlike traditional, protocol-heavy trials, it emphasises early discovery and incorporation of feedback, rapid field testing and continuous integration of operator insights. This method aligns projects with changing operational requirements and avoids wasted resources on non-viable systems. For India, merging technical and field trials into Integrated Project Teams, leveraging digital dashboards and prior certifications, and using prototype-first approaches would provide similar agility and efficiency.

Sustainment and Lifecycle

DAP largely views sustainment as a post-contract responsibility until disposal. SPEED integrates continuous capability evolution, emphasising spiral upgrades, iterative fielding and performance-based logistics (PBL). PBL is a defence acquisition strategy that emphasises outcome-focused, lifecycle product support—contracting for operational availability, reliability and cost-effectiveness of weapon systems instead of merely acquiring spares or services. PBL is now recognised globally as a best practice for sustaining complex assets in both new and legacy programmes, especially within the US Department of Defense.

PBL contracts define and incentivise performance metrics such as system availability, response times and cost reductions. Integrated logistics supporters (public or private) commit to maintaining defined readiness levels (e.g., 90 per cent fleet uptime, rapid part delivery, quick repair turnaround) at an agreed price over the contract’s term. PBL replaces transactional purchasing with sustained, comprehensive partnerships, encouraging suppliers to optimise supply chains, embed on-site skilled personnel, and proactively manage inventories and repairs for best operational outcomes.

Timelines and Policy Evolution

DAP typically measures time-to-field in years, making it less suited for rapidly evolving threats. SPEED compresses deployment timelines to 90–150 days,[vii] enabled by agile governance and early prototyping. Furthermore, while DAP advances through incremental policy updates, SPEED represents a fundamental culture shift, embedding DevSecOps, innovation, and speed as systemic values rather than exceptions. In essence, DAP 2020 reflects a compliance-driven legacy system, structured to ensure probity and layered checks at the cost of speed.

The SPEED Act 2025 represents a disruptive model, combining agility, innovation and operator-centric governance to deliver capabilities quickly. For India, the challenge lies in adopting SPEED’s core principles—iterative design, empowered governance, digital-first oversight and continuous evolution—while preserving the safeguards essential to public accountability. This mapping highlights the contrasts and opportunities for India to recalibrate DAP to deliver faster, more resilient and future-ready defence acquisition.

Table 2. Mapping of SPEED Act 2025 with Defence Acquisition Procedure (DAP)

| DAP 2020 Attribute | SPEED Act 2025 Attribute |

| Linear, Sequential Process (RFI : SQR : AoN : RFP : Trials : CNC/Contract) | Iterative, Outcome-Oriented, Dynamic, Empowered Governance |

| SQRs (Service Qualitative Requirements): Essential/Desirable | JRC + RAPID Framework: Outcome-Based, Early Experimentation |

| Traditional Contracting (Leasing, Buy/Make, Offsets for Large Buys) | Flexible Pathways: OTAs, BOOST Transition Funding, Agile Prototyping |

| Transfer of Technology, Indigenous Content | MOSA (Modular Open System Approach), Data Rights, Multi-Vendor Competition |

| Narrow Industrial Base via Offsets | Broad & Resilient Industrial Strategy, Non-Traditional Vendor Onboarding |

| Document-Centric, Paper-Based, Manual Digitisation | Streamlined Digital Reporting, Modernised Training, Empowered PEOs |

| User Trials, Long Protocols | Agile OT&E, Early Termination for Non-Performance, Speed Alignment |

| Lifecycle Focused on Sustainment to Disposal | Continuous Evolution, Product Support, and Iterative Fielding |

| Long Time-to-Field (Years) | Short Time-to-Field (90-150 Days), Fast Governance |

| Stepwise Policy Updates (Incremental) | Fundamental Culture/Process Shift (DevSecOps, Innovation, Speed Emphasis) |

Recommendations and Way Ahead

Empowered Body to Identify Joint Capability Gaps

The first and most significant recommendation is creating an Indian version of a Joint Requirements Council (JRC) as an empowered body that would fundamentally transform the way requirements are framed. Today, the DAP process is built on the foundation of Service Qualitative Requirements (SQRs), which tend to be rigid, highly technical, and often framed with a bias towards specific platforms or technologies. While SQRs provide clarity, they also restrict innovation, prevent flexibility, and, in many cases, lock the Services into specifications that become outdated even before procurement cycles are complete.

A body such as the JRC would replace this approach with capability gap identification at the joint level, considering the requirements of multiple Services, integrated theatre commands and emerging operational doctrines. Chaired by the Chief of Defence Staff or Vice Chief of Defence Staff, and with members from all three Services, DRDO, Integrated Defence Staff, and the IFA, this council could ensure that capability decisions are framed from a joint, mission-driven perspective rather than a single-service viewpoint.

Critically, this body would function on strict timelines of 90–150 days,15 ensuring that requirements are not delayed by years of paperwork and layered approvals. By concurrently processing cost, technology and experimentation streams, it could compress timelines drastically while improving decision quality. More importantly, it would frame outcomes rather than technical specifications. For example, instead of prescribing “a 40-ton tracked armoured vehicle with XYZ engine”, the body would define the operational outcome as “a platform capable of survivability, mobility, and firepower in mountainous terrain”. This subtle but transformative shift would allow industry—established defence majors and start-ups to propose diverse, innovative solutions.

Figure 1. Implementation Model for Capability Gaps Identification

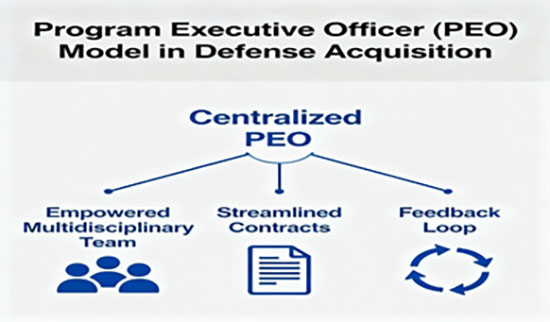

Programme Executive Officer (PEO) Model

The second recommendation is to adopt the Programme Executive Officer (PEO) model, a proven structure that decentralises authority and gives empowered programme leaders end-to-end responsibility. Under the current system in India, acquisition decisions are spread across multiple directorates, committees and Ministries, creating bottlenecks, micromanagement and rigid budgetary flows. This fragmented structure leads to years of delay in Contract Negotiation Committees (CNCs) and creates a culture where accountability is diffused rather than concentrated.

The PEO model would change this by vesting authority for an entire programme with a designated executive officer, supported by a small but empowered team of financial advisors, DRDO technical specialists, and contracting/legal experts. Such an officer would be responsible not only for overseeing prototype development but also for steering CNCs, re-phasing budgets when required, and ensuring spiral upgrades during the system’s lifecycle. This model would bring agility and accountability by collapsing layers of approvals into a single empowered authority.

One of the most significant advantages of the PEO system is its ability to shorten CNC cycles from several years to 3–4 months. This would be achieved by empowering the PEO to take financial calls within pre-approved ceilings, negotiate dynamically with vendors, and adopt innovative contracting pathways such as Other Transaction Authorities (OTAs) or rate contracts. By enabling continuous operator feedback, the PEO system would ensure that programmes remain relevant throughout their lifecycle rather than frozen at the point of contract.

Adopting PEOs would convert acquisition from a file-driven bureaucratic exercise into a programme-management discipline. This would align India’s acquisition governance with SPEED Act principles while ensuring that higher authorities maintain transparency and probity through digital dashboards and real-time oversight.

Figure 2. PEO Implementation Model

Reform Trials through Agile Evaluation and Digital Integration

The third recommendation is a comprehensive reform of India’s trial and evaluation system, which is currently among the most time-consuming phases of the procurement cycle. Today, trials are handled sequentially, starting with the Technical Evaluation Committee (TEC), then Field Evaluation Trials (FETs), and then User Trials. This leads to long timelines, repeated duplication of effort, and, in many cases, vendors dropping out midway due to the cost and uncertainty of the process.

The reform proposed is to merge TECs and FETs into Integrated Project Teams (IPTs) that would evaluate both technical and field requirements in a single, streamlined framework. These IPTs would employ prototype-first testing, digital simulations and twin-testing methodologies, reducing the need for repetitive, full-scale field trials at every stage. Acceptance of prior certifications from allied and partner nations could also cut duplication significantly, enabling faster movement through the testing cycle.

With such reforms, trial timelines could be compressed from over a year to as little as 3–6 months, making system induction faster and more cost-effective. Further, introducing real-time digital dashboards would give oversight bodies continuous visibility into trial progress, bottlenecks and outcomes. This would balance the need for speed with the imperative of transparency.

Figure 3. Integrated Project Team Working Model

Table 3. Key Recommendations for Reforming Indian Defence Acquisition

| Recommendation | Proposed Reform | Expected Impact |

| 1. Establish a Joint Requirements Council–India (JRC-I) | Create a Joint body (JRC-I) chaired by CDS/VCDS, with Vice Chiefs, IDS, DRDO, IFA; focus on capability gaps and outcome briefs; mandate 90–150 day approvals with concurrent cost-tech-experimentation. | It cuts the requirement approval cycle from years to months, encourages industry innovation (both traditional and start-ups), and ensures jointness and mission-level alignment. |

| 2. Adopt the Programme Executive Officer (PEO) Model | Empower PEOs with end-to-end programme authority (prototype, CNC, budget re-phasing, lifecycle); supported by IFA, DRDO, and legal specialists. | The CNC cycle is reduced from years to 3–4 months, enhancing accountability and agility and enabling spiral upgrades through operator feedback. |

| 3. Reform Trials through Agile Evaluation & Digital Integration | Merge into Integrated Project Teams (IPTs) using prototype-first testing, digital twins, real-time dashboards, and acceptance of prior certifications. | Trial timelines compressed to 3–6 months; Ensures transparency with digital monitoring; Allows early termination of non-performers; Improves operational relevance & speed. |

Conclusion

While the DAP 2020 has been a step towards greater indigenisation and streamlining, significant structural bottlenecks remain, leading to delays that adversely impact national security and operational readiness. The US SPEED Act 2025 illuminates how agile, outcome-based acquisition models can drastically shorten lead times from years to months through empowered decision-making, iterative development, modular contracting and digital integration. Key lessons drawn include the importance of decentralising authority by adopting Programme Executive Officer (PEO) roles, shifting from rigid Service Qualitative Requirements (SQRs) to a joint, mission-focused capability gap framework as exemplified by the proposed Joint Requirements Council-India (JRC-I), and fast-tracking trials through Integrated Project Teams (IPTs) leveraging digital simulations and prototype-first testing.

Implementing these reforms necessitates a cultural and procedural shift towards embracing agile methodologies, responsible risk-taking and continuous innovation, balanced with accountability and fiscal prudence. Incorporating digital workflows, real-time transparency dashboards, and early termination mechanisms for underperforming programmes will ensure efficient resource use and relevance of inducted systems.

This paradigm shift can transform India’s defence acquisition ecosystem into a more responsive, competitive and future-ready capability, aligned with the strategic imperatives of self-reliance (Atmanirbhar Bharat) and rapid adaptation to emerging threats. The recommendations offered provide a viable roadmap for policymakers to recalibrate procurement governance, compress timelines, incentivise indigenous innovation, and ensure the timely delivery of critical military capabilities that underpin India’s national security and global defence stature.

Views expressed are of the author and do not necessarily reflect the views of the Manohar Parrikar IDSA or of the Government of India.

[i] “Why SPEED is Crucial for India’s Defence Procurement”, Hindustan Times, 25 September 2025.

[ii] “SPEED Act Overview”, Armed Services Committee, June 2025.

[iii] “The Defence Ministry’s Biggest Test after Operation Sindoor”, India Today, 20 August 2025.

[iv] “Govt Likely to Recognise Foreign Defence Companies’ Local Arms as Indian”, Economic Times, 2 October 2025; “Defense Acquisition Reform Takes Center Stage with SPEED Act”, IDGA, 17 September 2025.

[v] “House Armed Services Leaders Unveil Bill to Reform Defense Acquisition Requirements Process”, DefenseScoop, 8 June 2025.

[vi] “Govt Likely to Recognise Foreign Defence Companies’ Local Arms as Indian”, no. 4.

[vii] “Defense Acquisition Reform Takes Center Stage with SPEED Act”, no. 4.